Complete Analysis on Why Does The Bearing Cage Break Easily 2019 [ Right Now]

Complete Analysis on Why Does The Bearing Cage Break Easily 2019 [ Right Now]

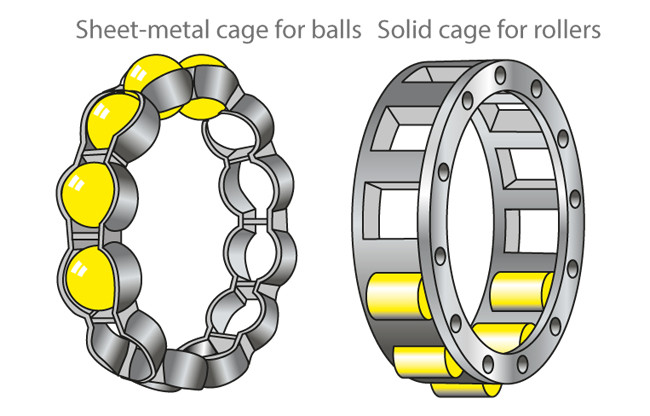

The bearing cage in the rolling bearing plays the role of equidistance separating the rolling body and preventing the rolling body from falling, guiding and driving the rolling body to rotate.

Although the bearing has a lot of parts, the bearing cage is often the first parts damaged (failure). Bearing cage has another name "blood vessel" of the bearing. The inner ring, the outer ring, rolling body evenly and orderly distribution, a little error is easy to shorten the service life of the bearing, even damage.

What causes the bearing cage to break?

◐ ◑ Bearing cage lubrication

Lubricating oil or grease dry, not timely added (maintenance), lubricating oil or grease with the wrong label.

◐ ◑ Bearing impact load

The violent vibration in the impact load produces the impact of the rolling body on the cage.

◐ ◑ Bearing cage cleanliness

The bearing has a poor seal in the bearing box, dust may enter. There will be friction between the rolling body and the cage, thus causing damage to the cage.

◐ ◑ Installation problem

Install bearings incorrectly and damage the cage during installation.

◐ ◑ Bearing creep phenomenon

Creep mostly refers to the sliding phenomenon of the ring. Under the condition of insufficient interference of the mating surface, the load point moves in the direction of the surrounding due to sliding, resulting in the deviation of the ring from the position of the ring relative to the axis of the shell towards the circumference.

◐ ◑ Bearing cage abnormal load

Installation does not reach the designated position, slope, etc of the large amount of interference of the clearance is reduced, increasing friction heat production, the surface of the softening, abnormal early spalling, along with the expansion of peeling, flaking, foreign body into the cage pocket hole lead to keep running block and generate additional load, aggravated the wear and tear in the cage, the cycle of such deterioration, it may cause maintains a fracture.

◐ ◑ Bearing retainer material defects

Cracks, large non-metallic inclusions, shrinkage holes, air bubbles, riveting defects, lack of nails, padding nails, gaps in the bonding surface of two half retainers, and serious riveting injuries may cause retainer fracture.

◐ ◑ Bearing hard foreign invasion

The invasion of foreign hard foreign matter or other impurities aggravates the wear and tear of the cage. For the above reasons to solve, the bearing life will be very long. Many bearing damage is not due to the life of the bearing itself, but caused by many external environment, such as insufficient lubrication, dust entry, installation error, excessive load, excessive temperature, coupling is not medium.

◐ ◑ For other reasons

If the coupling is not correct, bearing skew, stress uneven; Belt installation is too tight; Environmental problems and so on can damage the bearing or cage.

At last, above is all about affecting factors of bearing ring damage. If you have any questions about bearing parts please feel free to email me or leave a comment.