11 Useful Methods on Rolling Bearing Lubrication 2020 [Right Now]

11 Useful Methods on How to Lubricate Rolling Bearings 2020 [Right Now]

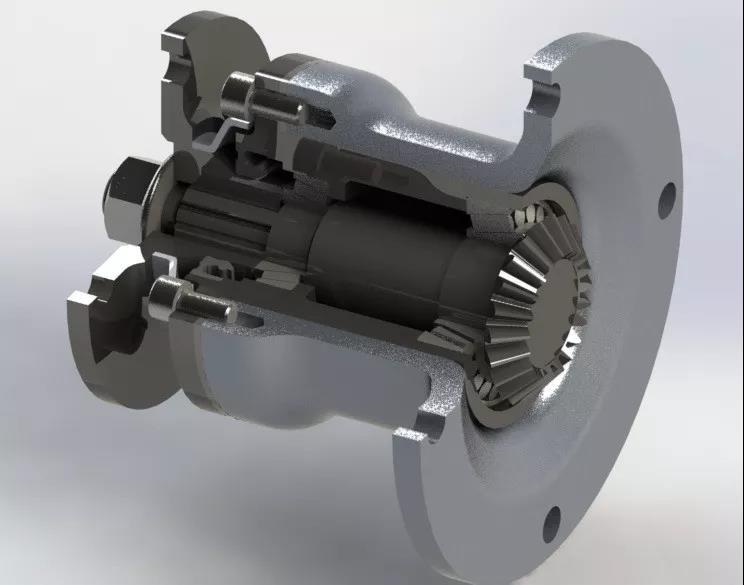

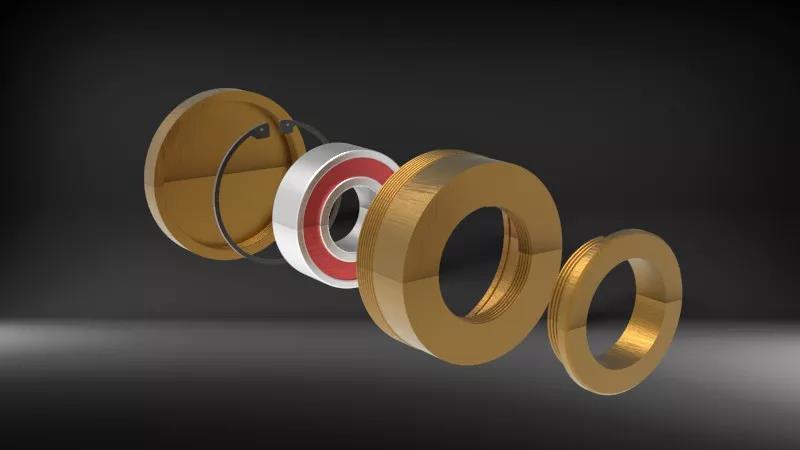

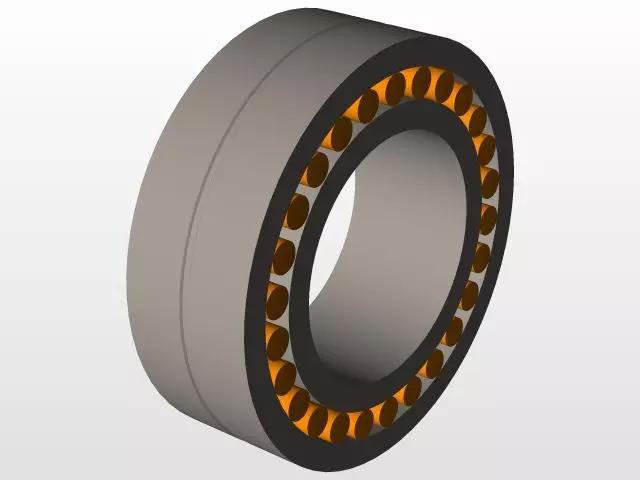

Rolling bearing lubrication is to enable the bearing to operate normally. Avoid direct contact between the raceway and the surface of the rolling body. Reduce the friction and wear inside the bearing. Extend the bearing service life. Enhance the performance of the bearing, but also to prevent foreign matter from intruding into the bearing and causing rust and corrosion.

1. Manual lubrication

This is the most primitive method, in the case of insufficient lubricating oil-bearing, oil supply with oiler. But this method is difficult to maintain a certain amount of oil. Because the risk of forgetting refueling is greater, usually only used for light load, low speed or intermittent movement occasions. When it operates, set a dust cover or ball valve on the fuel hole, and use felt, cotton, wool, etc. as a filtering device.

2. Drop point lubrication

Usually used for bearing with circumferential speed less than 4-5m /s, light load, and medium load. From the container through the hole, needle, valve, and other lubricating oil supply are roughly quantitative. The most classic is the oil drip oil cup. The amount of oil drip varies significantly with the viscosity of the lubricating oil, the bearing clearance and the position of the oil supply hole.

3. Oil ring lubrication

By hanging on the shaft and rotating the ring to the oil pool lubrication bearing (can use horizontal shaft lubrication method). It is suitable for a bearing diameter greater than 50mm medium speed and high-speed bearing. The oil ring preferably seamless, bearing diameter ratio less than 2, can only use one oil ring, otherwise, it needs two oil rings.

4. Rope lubrication

Relies on the capillary and siphon action of the oil rope to guide the oil in the oil cup into the bearing. Mainly used for light and medium load bearings with peripheral speeds less than 4 ~ 5m / s. In addition, the oil rope can play a filtering role in the whole process.

5. Oil pad lubrication

Use the capillary action of the oil pad to apply the lubricant from the oil pool to the surface of the journal. This method can keep the friction surface clean, but the dust can also block the pores and cause insufficient oil supply. The oil supply for pad lubrication is usually only 1/20 of that for oil lubrication.

6. Oil bath bearing lubrication

This lubrication method is a part of the bearing immersed in lubricating oil. It is often used for thrust bearings of vertical shafts, not for radial bearings of horizontal shafts.

7. Splash lubrication

Supply the lubricating oil to the bearing by the blow of rotating parts in the oil tank. It is suitable for bearings with a higher speed.

8. Spray rolling bearing lubrication

The method of spraying lubricating oil on the friction surface after atomizing is suitable for high-speed bearing.

9. Pressure oil supply for bearing lubrication

Supply oil to the bearing by the pressure of the lubrication pump. And recycle the lubricating oil flowing from the bearing to the oil pool for recycling. It is the most stable lubrication method with the largest amount of oil supply. It is suitable for high-speed, heavy load and important sliding bearings.

10. Circulating oil lubrication

Deliver the filter oil to the bearing parts with the oil pump. Filter and cool the lubricating oil after passing through the bearing. Because the circulating oil can take away a certain amount of heat and cool the bearing. The method is suitable for bearing parts with higher rotating speed.

11. Rolling bearing jet lubrication

The high-pressure oil is injected into the bearing through the nozzle with the oil pump, and the injected oil flows into the oil groove through the other end of the bearing. When the bearing rotates at a high speed, the rolling body and the cage also make the surrounding air form airflow at a relatively high rotation speed. It is difficult to send the lubricating oil into the bearing by the normal lubrication method. At this time, the lubricating oil must be sprayed into the bearing by a high-pressure injection method, and the nozzle position should be placed between the inner ring and the center of the cage.

Bearing lubrication is a continuous work, lubricating oil replacement cycle based on the use of bearing conditions and the amount of oil. Under normal circumstances, when the operating temperature is below 50℃ and the good environment with less dust is used, replace it once a year. When the oil temperature reaches 100℃, replace it for 3 months or less.