7 Effective Tips on How to Maintain Rolling Element Bearing

7 Effective Tips on How to Maintain Rolling Element Bearing

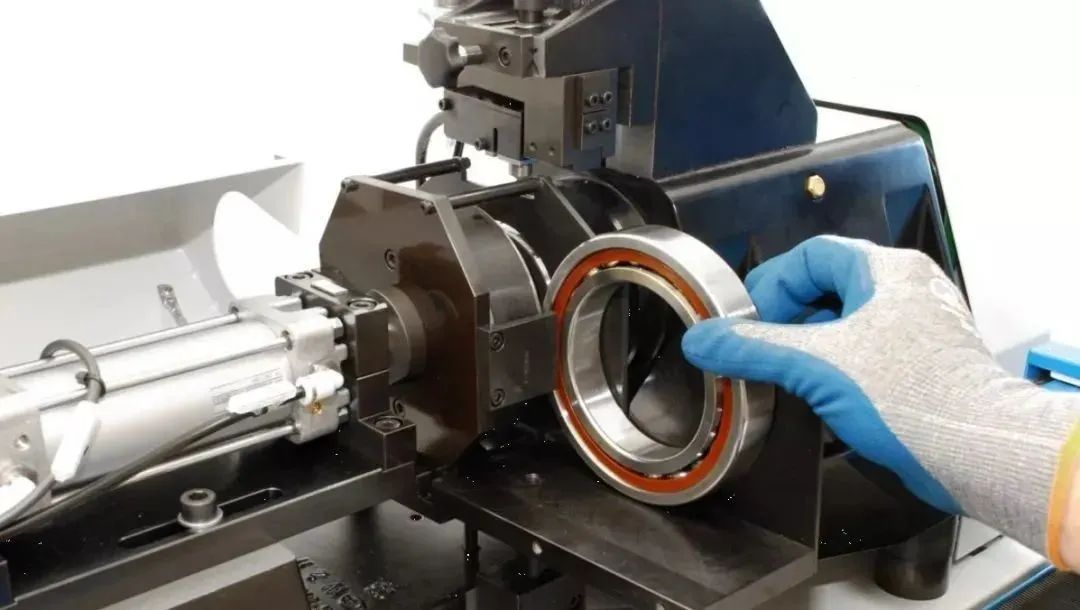

Bearing inspection

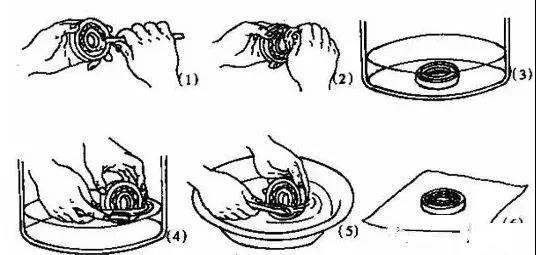

Bearing cleaning

When disassembling the bearing for maintenance, first record the appearance of the bearing. Then confirm the remaining amount of lubricant, take a sample of the lubricant for inspection, and wash the bearing. The cleaning agent generally uses ordinary gasoline and kerosene.

The cleaning of the removed bearing has rough cleaning and fine cleaning. Put them in the container, and put them on the bottom of the metal mesh first, so that the bearings do not directly contact the stolen goods of the container.

During rough cleaning, if you rotate the bearing with dirt, it will damage the rolling surface of the bearing. In the rough cleaning oil, use a brush to remove grease and adhesions. After it is roughly clean, switch to fine cleaning.

Fine washing is to wash the bearing carefully while rotating it in the washing oil. In addition, the cleaning oil should always be kept clean.

Bearing damage and bearing maintenance

① There are cracks or gaps in any one of the inner ring, outer ring, rolling element and cage;

② There is a break on any one of the ring and rolling element;

③The raceway surface, ribs, and rolling elements are significantly stuck;

④ The cage is significantly worn, or the rivets are significantly loose;

⑤There are rust and scratches on the raceway surface and rolling elements;

⑥ There are serious indentations and marks on the raceway surface and rolling elements;

⑦ There is obvious creep on the inner warp surface of the inner ring and the outer warp surface of the outer ring;

⑧ Discoloration caused by heat is obvious;

⑨Bearing sealed with grease, the seal ring or dust cover is obviously damaged.

Precautions for bearing maintenance

Rolling bearings are precision parts, no matter how high-performance bearings they are, if you use improperly, they will not get the expected high performance. Precautions for the use of bearings are as follows:

Keep the bearing and surrounding environment clean

Even if tiny dust invisible to the naked eye enters the bearing, it will increase bearing wear, vibration and noise. You should keep bearings and their surrounding accessories clean, especially dust and dirt. Tools and environment must also be clean.

Precautions during installation

Don't press forcefully, directly hit the bearing with a hammer, and not to transmit pressure through the rolling elements.

Use the correct installation tool

Try to use special tools and try to avoid using things like cloth and short fibers.

Prevent bearing corrosion

When holding the bearing directly by hand, wash away the sweat from your hands and apply high-quality mineral oil before operation. Pay special attention to rust prevention in the rainy season and summer. However, under certain special operating conditions, bearings can obtain a longer life than traditional calculations, especially under light load conditions.

These special operating conditions are the surface damage that may be caused when the rolling surface is effectively divided by a lubricating oil film and limits contaminants. In fact, under ideal conditions, the so-called permanent bearing life is possible.

Common problems and countermeasures in bearing maintenance

1. Abnormal load: select appropriate assembly clearance and preload.

2. Poor assembly: improve the machining accuracy of the shaft and improve the installation method.

3. Insufficient lubricant: supplement or use suitable lubricant.

The rotation vibration of the shaft is large

1. Spalling: fatigue spalling, replace the bearing.

2. Poor assembly: improve the machining accuracy of the shaft and improve the installation method.

3. Foreign matter intrusion: clean relevant parts and use clean grease.

Lubricant leakage for bearing maintenance

1. Too much lubricant: reduce lubricant.

2. Foreign body intrusion: clean related parts.