What Are The Characteristics of Thin Wall Deep Groove Ball Bearings?

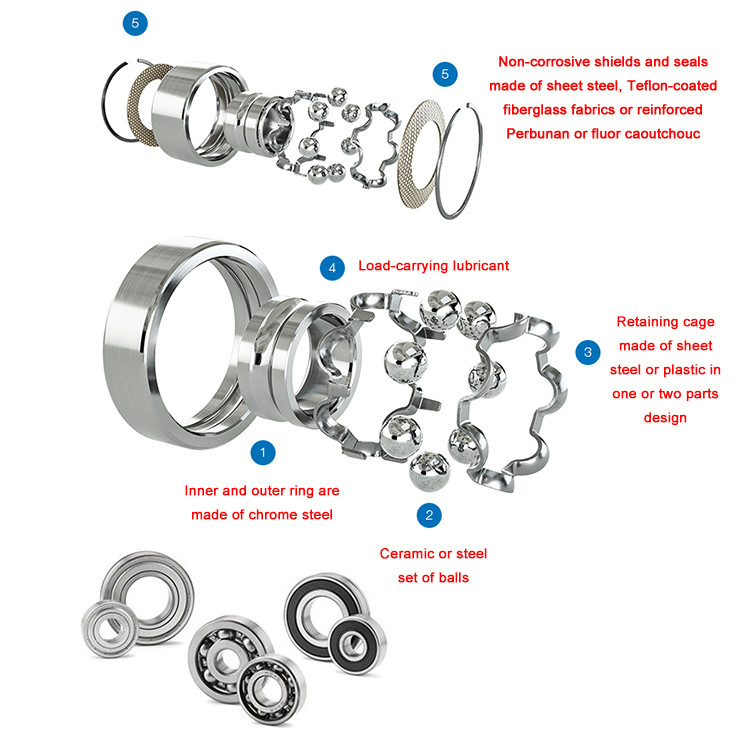

Deep groove ball thin wall bearing is a very common bearing type in rolling bearings. It is basically composed of an outer ring, an inner ring, a group of steel balls, and a group of retainers. There are two types: single row and double row. The deep groove ball thin wall bearing is characterized by small friction resistance and high rotating speed. It can be used on the machine parts bearing radial load or the combined load of radial and axial simultaneously, and can also be used on the machine parts bearing axial load.

1. Sealing and dustproof

The standard industrial seal is usually made of nitrile rubber. It can also provide customized seals for deep groove balls and thin wall bearings with silicone rubber, bearing materials, etc. to meet high temperatures and other extreme conditions that may be encountered.

2. Plating

It can provide a very thin and compact chromium coating to give the deep groove ball and a thin wall bearing a stronger corrosion resistance against the ultra-strong corrosion requirements. Different from many traditional plating, the coating will not be subject to skin grafting or flaking under pressure, so it can maintain corrosion resistance and reduce wear. The performance of the coating has been proven in the key military, aviation, and deep space applications.

3. Lubrication

The deep groove ball thin wall bearing provides a full range of lubricants, enabling you to improve the performance of the bearing in applications with special requirements such as moisture resistance, high temperature, low temperature, vacuum, and low torque.

4. Internal cooperation

The deep groove ball thin wall bearing can meet the expected operating performance requirements by improving the internal fit. The preload bearing is used for high stiffness applications, and the radial clearance bearing is used for low friction torque applications. In addition, standard cross roller bearings usually do not have anti-corrosion protection measures, as well as customized seals, special application grease, and high-temperature adaptability for extreme environments.