Why Do People Choose to Use The Linear Guides

Why Do People Choose to Use The Linear Guides

High positioning accuracy

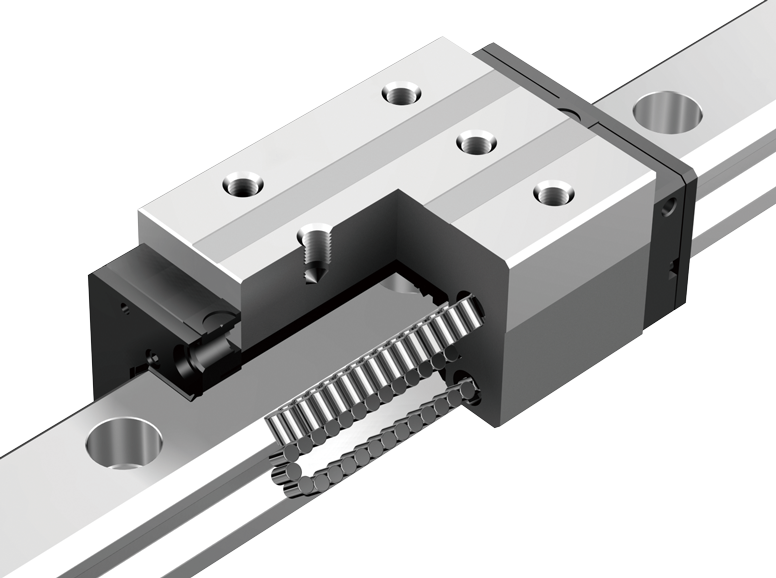

The rolling of the steel ball makes the motion of the rolling linear guide. The friction resistance of the guide rail pair is small, the difference between dynamic and static friction resistance is small, and it is not easy to crawl at low speed.

High repetitive positioning accuracy, suitable for moving parts that frequently start or change directions.

People can set the positioning accuracy of the machine tool to the super micron level. At the same time, increase the preload appropriately according to the needs. Ensure that the steel ball does not slide, realize smooth movement, and reduce the shock and vibration of the movement.

Small erosion

For the fluid lubrication of the sliding guide surface, due to the floating of the oil film, it is inevitable that there will be movement accuracy errors. In most cases, fluid lubrication only exists in the boundary area limitedly. Metal contact causes direct friction is unavoidable. This kind of friction will waste a lot of energy.

On the contrary, rolling contact friction consumes less energy, which reduces the friction loss of the rolling surface, so the rolling linear guide system can be in a high-precision state for a long time. At the same time, the use of lubricating oil is also very small, which makes it very easy to design and use and maintain the lubrication system of the machine tool.

Adapt to high-speed movement and greatly reduce drive power

Strong carrying capacity

Easy to assemble and interchangeable

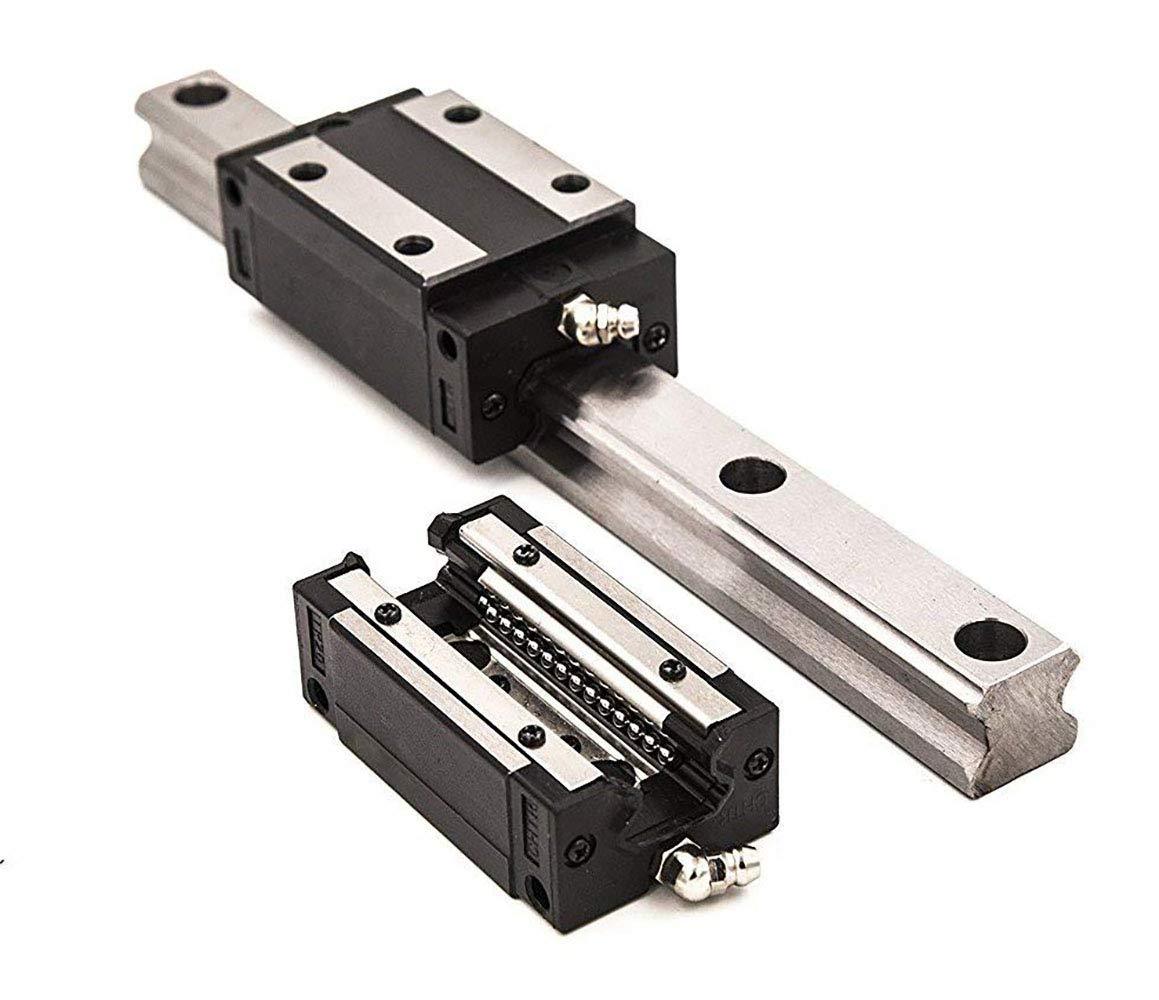

People using traditional sliding guide rails must scrape the guide rail surface, which is time-consuming and laborious. And once the accuracy of the machine tool is poor, people must scrape it again. The rolling guide is interchangeable. You only need to replace the slider or the guide rail or the entire rolling guide, and the machine tool can regain high precision.

Since the relative movement of the ball between the guide rail and the slider is rolling, fit can reduce friction loss. Usually, the rolling friction coefficient is about 2% of the sliding friction coefficient. Therefore, the transmission mechanism using the rolling guide is far superior to the traditional sliding guide