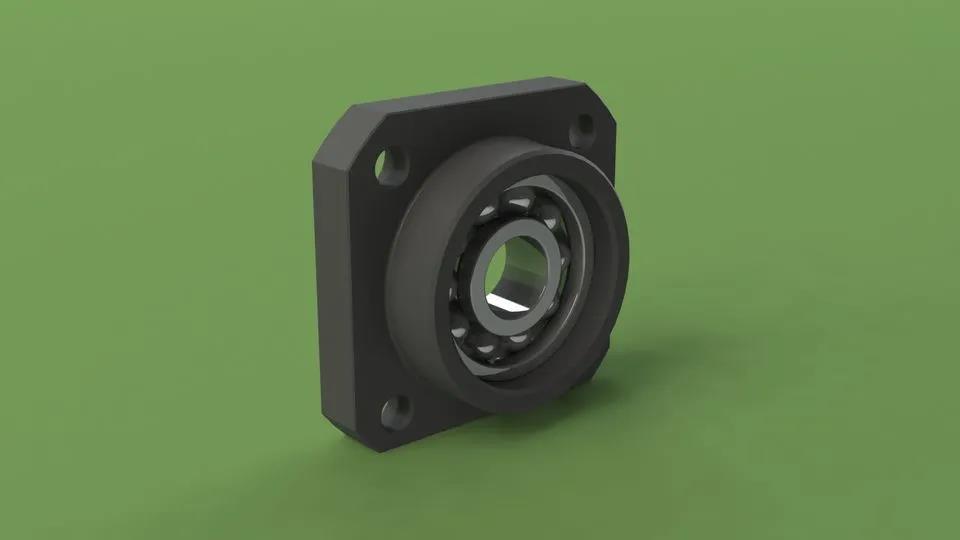

Top 5 Steps on How to Install Bearings Correctly

Top 5 Steps on How to Install Bearings Correctly

Use special tools for bearing installation and disassembly

Advanced installation tools can avoid bearing damage caused by improper tools and operations during installation. For example, when installing the bearing, the staff used the copper rod knock-in method. This can easily cause uneven axial force of the bearing. This will also cause deformation of the cage, damage to the rolling elements, and increased clearance.

In addition, during the knocking process of the copper rod, the copper powder flies into the bearing cage, which is easy to cause bearing failure.

Do the bearing inspection work before installation

For old bearings, check whether there are burrs, scratches, or cracks on the surface of the ball (roller). Qualify the radial clearance and axial clearance of the old bearing, generally only measure the radial clearance.

Check the matching size of the bearing and the rotor shaft

Control the amount of oil in the bearing and the bearing chamber

Too much oil in the bearing and the box will cause the bearing rolling elements to slip. Cause the rollers to change from rolling friction to sliding friction and damage the bearing rolling elements. Due to the excessive amount of bearing oil, the free space in the bearing box is small. And the operating temperature of the bearing will rise.

The lubricating grease density is reduced, the rolling element lubricating oil film becomes thinner, and the lubrication condition is poor. This will easily cause abnormal noise of the bearing, loss of surface slip, and shorten the life of the bearing.

In the actual work process, for bearings that run at high temperature and high speed, people should try to minimize the use of bearings with seal. Increasing the amount of oil in the motor oil cover and installing a refueling nozzle can increase the operating life of the motor bearing.