Bearings for Our Country Tunnel Construction

Bearings for Our Country Tunnel Construction

The construction of two cross-sea passages in my country's north and south set another world record

On December 9th, my country ushered in an unprecedented historic moment in the history of the construction of a cross-sea immersed tube tunnel. Installation of the first section of the Dalian Bay Subsea Tunnel, the first cross-sea immersed tube tunnel in northern my country. Achieve zero breakthroughs in immersed tube tunnel construction in cold regions. Completed the E6 pipe joint installation in the deep and middle channels. The world's longest and widest steel shell immersed tube tunnel is approaching the kilometer mark, setting another record in length.

Two major super projects, one south, and one north completed key nodes on the same day. This created a new record in the field of cross-sea channel construction in China and the world. It demonstrates my country's strong comprehensive coordination, resource coordination, and scientific and technological research and development capabilities in the construction of cross-sea channels. Effectively promote the development of transportation in the old Northeast industrial base and the Guangdong-Hong Kong-Macao Greater Bay Area.

Bearings also play a vital role in pipeline construction. And, people most commonly use pillow block bearings and deep groove ball bearing.

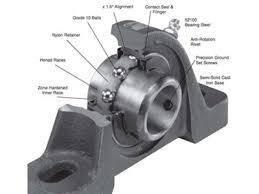

Pillow Block Bearing

Pillow block bearing consists of an outer spherical ball bearing with seals on both sides and a cast (or stamped steel plate) bearing housing. The internal structure of a pillow block bearing is the same as that of a deep groove ball bearing, but the inner ring of this type of bearing is wider than the outer ring. The outer ring has a truncated spherical outer surface. This can automatically adjust the center when matched with the concave spherical surface of the bearing housing.

Usually, there is a gap between the inner hole of this kind of bearing and the shaft, and the inner ring of the bearing is fixed on the shaft with a jack wire, an eccentric sleeve, or an adapter sleeve, and rotates with the shaft. Therefore, the bearing with seat has compact structure, convenient installation, and unloading, perfect sealing, suitable for simple support, and is often used in mining, metallurgy, agriculture, chemical industry, textile, printing, and dyeing, conveying machinery, etc.

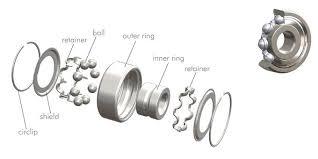

Deep Groove Ball Bearing

The deep groove ball bearing is the most popular bearings in the rolling bearing. Because it has features of low frictional resistance and high speed. It can bear radial load or a combined load that acts on both radial and axial directions, and can also bear axial load.

Deep groove ball bearings have applications in gearboxes, instruments, motors, household appliances, internal combustion engines, transportation vehicles, agricultural machinery, construction machinery, construction machinery, roller skates, yo-yos, etc.

Our Company

Sheng Yao Wang (Dalian) International Trade Co., LTD. has been focusing business of bearing production and trade for 21 years, has rich experiences in bearing processing and trade, to provide clients with professional bearing application solutions. Our factory is located in the ZWZ bearing industry zone of China, our professional r & d team, advanced processing equipment, and technology as well as perfect quality control system, create high-quality bearing products.

Our factory has a full set of production lines for bearing rings and cages, ranging from material preparation, forging, stamping, grinding, heat treatment, shaping, boring, to surface treatment, etc. We keep controlling the quality of each processing, focusing on the production of the rolling bearing in the scope between 100mm and 800mm inner diameter, outside diameter within 300-900mm.

We have obtained international quality standard certification of ISO9000 and ISO14000 only to improve customer satisfaction and experience of bearing usage.