Do You Have Bearing Installation Problems That 90% of People Make Mistakes?

Do you have bearing installation problems that 90% of people make mistakes?

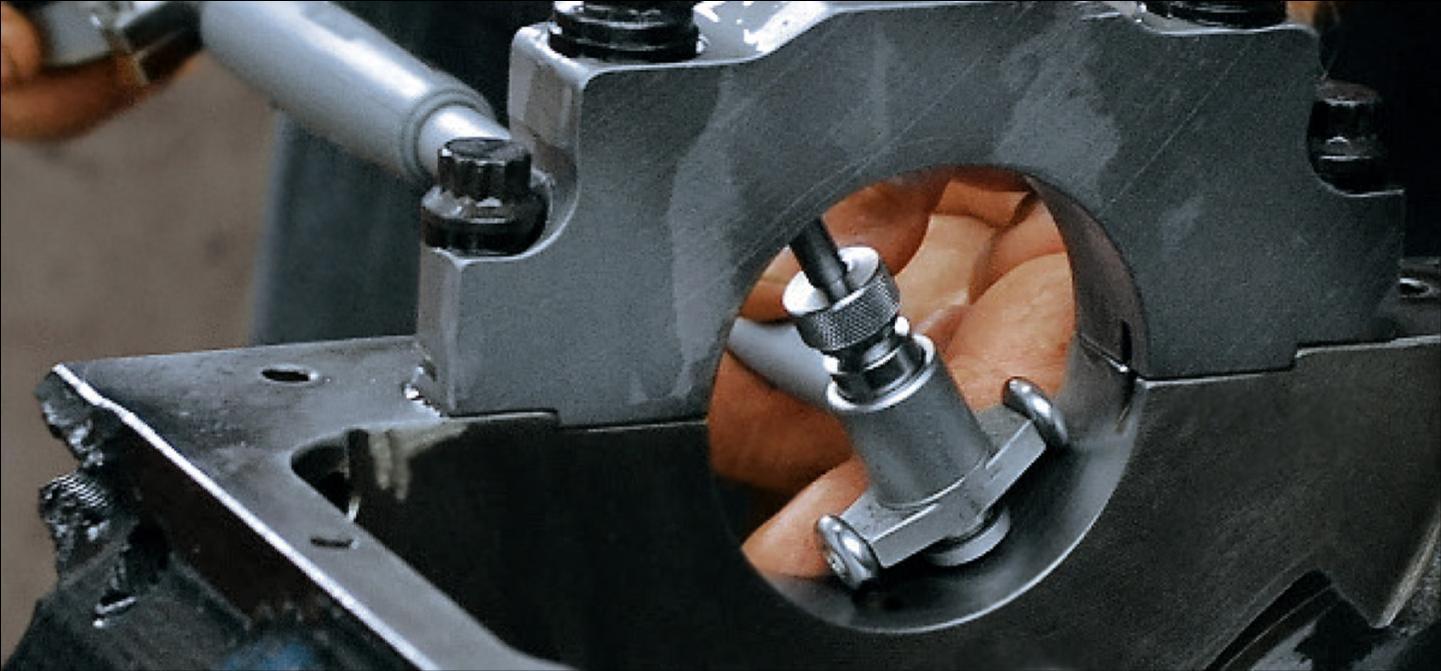

Use special tools for bearing installation and disassembly

Advanced installation tools can avoid bearing damage caused by improper tools and operations during installation.

For example, when installing the bearing, the staff used the copper rod knock-in method. It is easy to cause the uneven axial force of the bearing, causing deformation of the cage, damage to the rolling elements, and larger clearance. And the copper rod is in the process of striking. The copper powder flies into the bearing cage, which is easy to cause bearing failure.

Do the bearing inspection work before installation

For old bearings, check whether there are burrs, scratches, or cracks on the surface of the ball (column). Whether the radial clearance and axial clearance of the old bearing are qualified, generally only the radial clearance needs measure.

For new bearings, first, check whether the bearing model is correct. Refer to Table 1 for the radial clearance standards of rolling bearings. For example, Model 6318 deep groove ball bearing, bearing inner diameter 90mm, its radial clearance range is 0.016~0.046mm, the maximum wear of the bearing can is also 0.25mm.

Check the matching size of the bearing and the rotor shaft

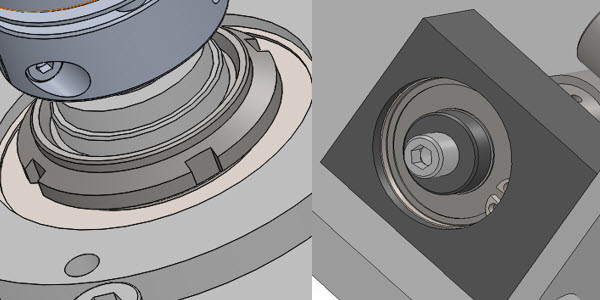

Control the amount of oil in the bearing and the bearing chamber

Excessive oil in the bearing and the box will cause the rolling elements of the bearing to slip, causing the rolling friction to change from rolling friction to sliding friction, which will damage the rolling elements of the bearing.

Due to the excessive amount of oil in the bearing, the free space in the bearing box is small. And the operating temperature of the bearing will be reduced. As it rises, the lubricating grease density decreases. The lubricating oil film of the rolling elements becomes thinner. And the lubrication conditions are poor. It is easy to cause abnormal noise of the bearing, surface slippage, and shorten the life of the bearing.

Generally, there is a bearing oil chamber on the side of the motor end cover.

In the actual working process, for bearings running at high temperature and high speed, bearings with sealing surfaces should be used as little as possible, increasing the amount of oil in the motor oil cover, and installing a refueling nozzle, which can increase the operating life of the motor bearing.

Pay attention to ensure that the insulation is intact

For bearings with an insulation design on the outer ring, care must be taken to ensure that the insulation is intact. If the bearing insulation is damaged during installation, the thin oil film of the bearing will be broken down by the shaft voltage.

After the oil film breaks down, not only will the lubrication conditions of the rolling elements be poor, but also the electric sparks generated will form electrical corrosion on the rolling elements of the bearing and cause the rolling elements. The surface is not polished, which accelerates the wear of the bearing.