How Do Gearbox Bearing Operate in Wind Turbine [Quick]

How Do Gearbox Bearing Operate in Wind Turbine [Quick]

The gearbox bearing generally uses radial ball bearings and cylindrical roller bearings. The shaft speed determines the gearbox bearing design.

The wind turbine gearbox is a very important part of the Draught Fan. Due to the constant impact from the variable load and strong gust, it's different from the common gearbox in design, manufacture, and maintenance. And with the improvement of the Draught Fan’s design power, wind power gearbox on the premise of meet the load. The volume must be as small as possible, the weight must be as light as possible. But it still can reach more than 20 years of service life.

The domestic and international application shows that the bearing is one of the weakest links in all parts of wind turbine gearbox. This paper will take the most common wind power gearbox design as an example. It introduces how to improve the reliability of wind power gearbox by analyzing the application of bearing.

Analysis of bearing area of wind power gearbox bearing:

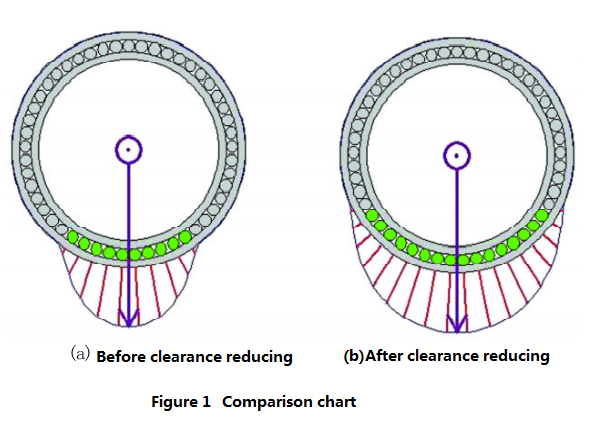

In the roller of the bearing, there is usually only one part of the roller bearing the load, and this part of the roller is the bearing area of the bearing. If the bearing area is too small, the rollers are prone to skidding during actual operation. At present, in the design of wind turbine gearbox, two single rows tapered roller bearings or two schemes with full roller bearings are used. Improve the bearing area by means of proper pre-tightening of tapered roller bearings or by reducing the clearance of cylindrical roller bearings, as shown in figure 1.

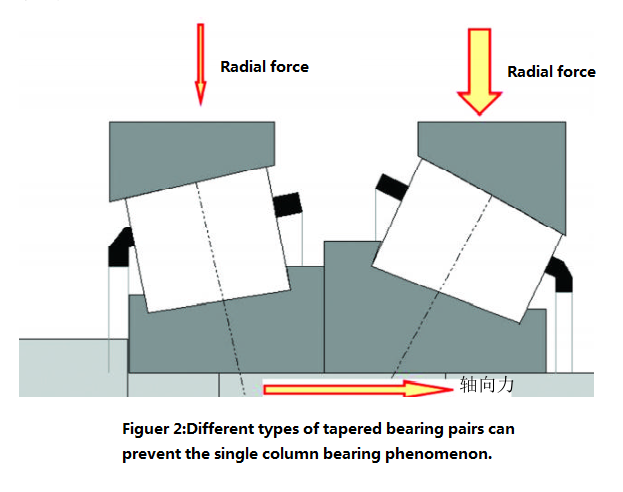

This method solves the problem of pitting and peeling of ball bearing in traditional ball bearing and cylindrical roller bearing. However, you should also care about preventing a single column load. In this case, conical bearings with different cone angles can be considered for mating use, as shown in figure 2.

In conclusion, the analysis of the bearing area of bearing can understand the running state of bearing well, so as to optimize the selection of bearing and perfect gearbox design.